WELDING

The impossibility to check the weldings without destructive processes makes it necessary to carry out preventive and indirect control.

Direct checks of weldings quality without destructive tests are often expensive or not possible. In order to minimize defects, through the years we have assesses robust welding procedures and have qualified all our welders.

These qualifications are guaranteed by:

- UNI EN ISO 3834-2 certification

- Qualification of welders ISO 9606-1

- Qualification of welding procedures UNI EN ISO 15614-1

The non-destructive surface and volumetric tests carried out in the company (VT, PT, RT, LT) are performed by qualified personnel in accordance with UNI EN ISO 9712.

The welding processes currently used:

- UNI EN ISO 4063 141 (TIG)

- UNI EN ISO 4063 135 (MAG)

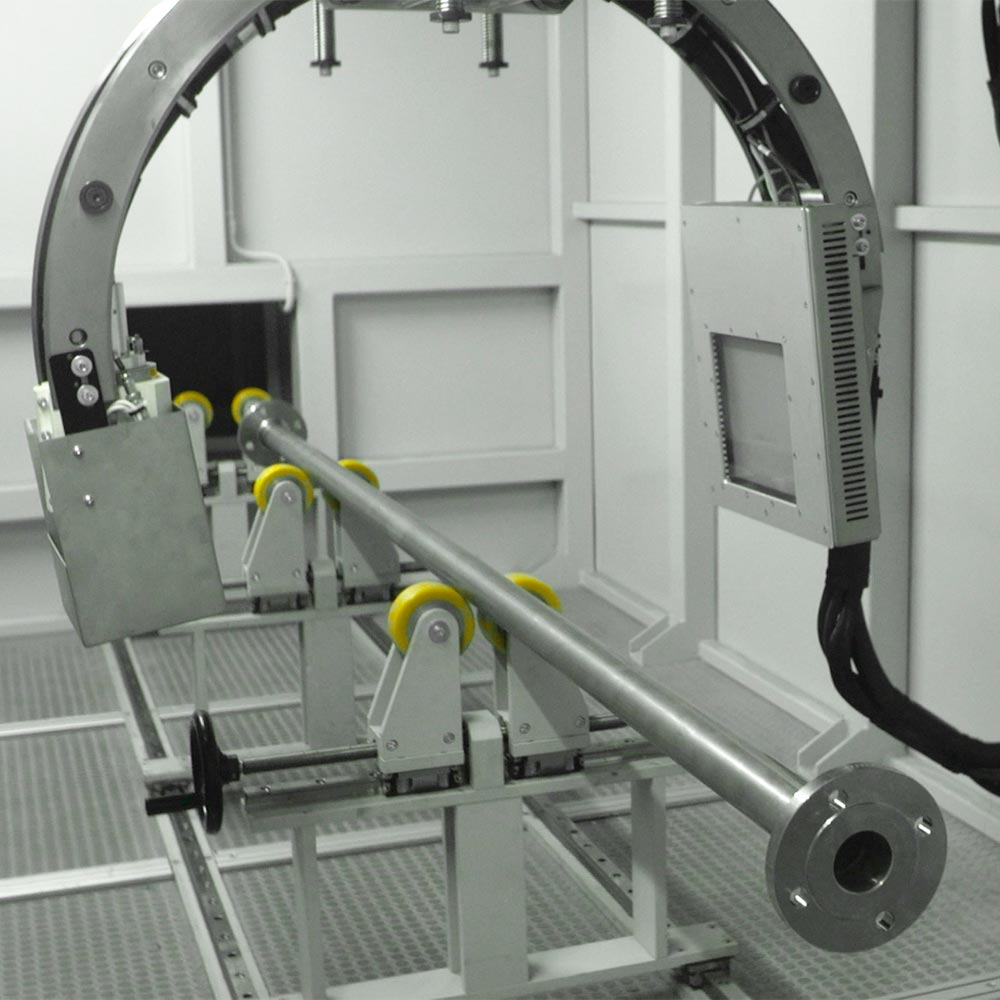

The lifting/handling systems are suitable for the assembly, positioning, and welding of large pipes.

Pipe assembly is performed with NC (Numerical Controlled) universal mechanical templates.